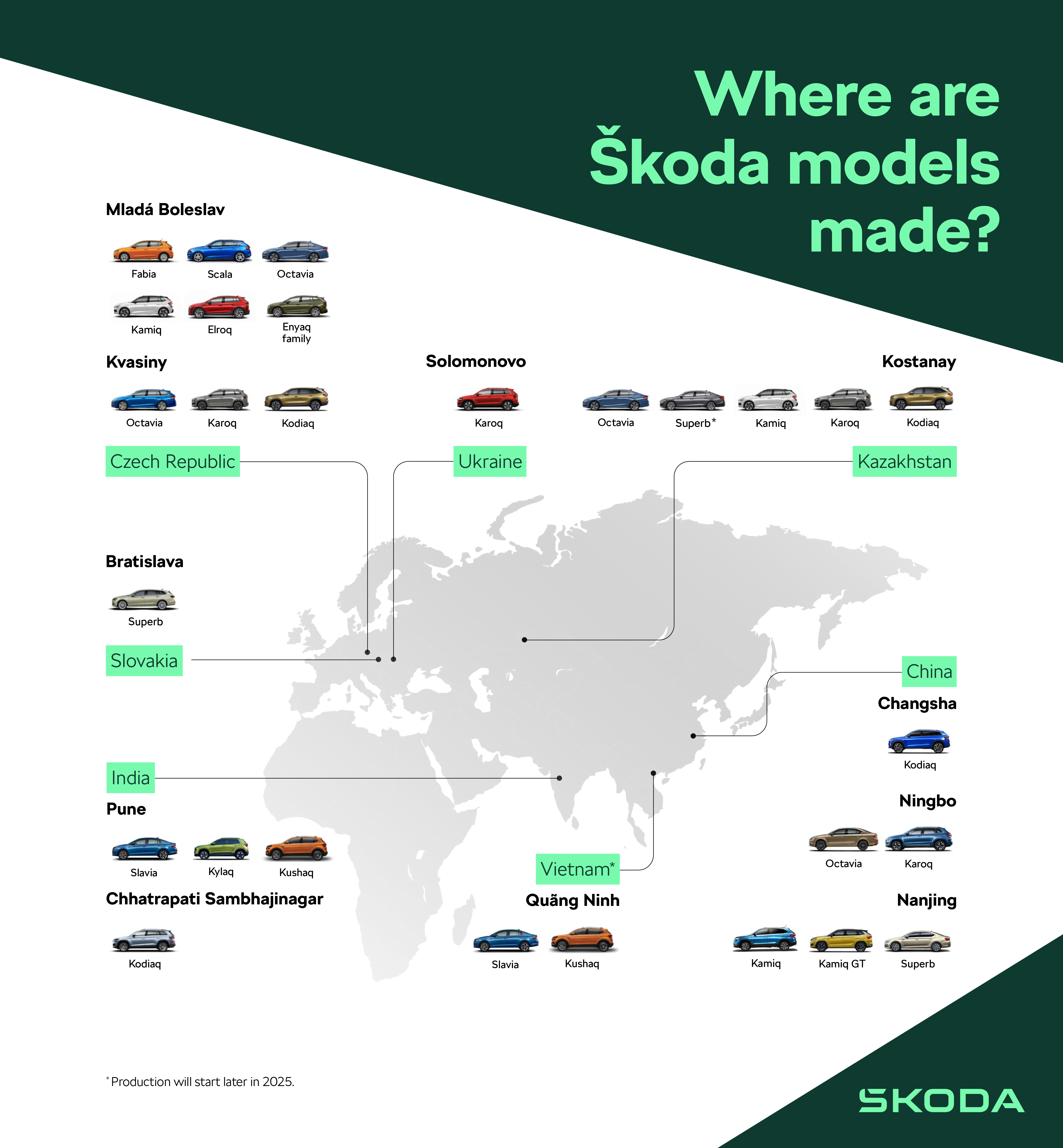

In 2024, Škoda Auto manufactured over 925,000 vehicles at its global production facilities, a year-on-year increase of 4.2%. Additionally, the company produced more than 280,000 battery systems for electric and plug-in hybrid vehicles across the Volkswagen Group, over 1 million transmissions and nearly 500,000 engines. The main plant in Mladá Boleslav accounted for the share of this success by producing 575,000 Škoda vehicles. In 2024, production of a record number of new and refreshed models began, including the Scala, Kamiq, Kylaq, Octavia and Kodiaq model series. The company also continued to strengthen its international operations: capacity at the Pune plant in India was expanded for the Kylaq compact SUV, Škoda’s third model made in India for India. Additionally, preparations for vehicle assembly in Vietnam were finalised, and Kodiaq SKD production started in Kazakhstan.

“From a Production perspective, 2024 was one of the most challenging years in Škoda Auto’s history. This was due to the launch of a record number of new vehicles, the expansion of our international production capacities, and further optimisation of manufacturing processes. I want to thank the entire Production and Logistics team for the dedication and hard work, which have been key to achieving this outstanding result. Last year, we took important steps to boost our competitiveness and efficiency, including the logistically demanding partial relocation of the Octavia’s production to Kvasiny. This move freed up capacity on our unique, flexible production line in Mladá Boleslav, which accommodates both ICE vehicles and electric vehicles, making way for the new Elroq model range.”

Andreas Dick, Škoda Auto Board Member for Production and Logistics

Car production in the Czech Republic

Škoda Auto’s Czech plants remain the biggest contributors to its global car production. The Mladá Boleslav plant increased its production to 575,000 (+3.4%) vehicles last year, having partially relocated production of the best-selling Octavia.

In 2024, the Fabia, updated versions of the Scala, Octavia, and Kamiq, as well as the fully electric Enyaq and Enyaq Coupé models rolled out from the Mladá Boleslav plant. Despite increasing competition and an industry-wide slowdown in demand for fully electric vehicles, the Enyaq range attracted strong customer interest, with Škoda Auto manufacturing nearly 80,000 units last year.

The production line in Mladá Boleslav is unique in the Volkswagen Group in its ability to simultaneously produce vehicles with internal combustion engines on the MQB platform and electric vehicles on the MEB platform. This flexibility enhances production efficiency and allows the plant to respond swiftly to changes in demand. By the end of the year, preparations were completed for the series production of the all-new Elroq, with a daily production capacity of up to 600 units.

The Kvasiny plant, celebrating 90 years of operation in 2024, also delivered strong results, producing 248,000 vehicles. This site primarily focuses on the new generation of the Kodiaq model and Karoq, with the updated Octavia recently added to its production portfolio.

Production of engines, transmissions, and battery systems

The Mladá Boleslav plant is also a major producer of components. Last year, it manufactured nearly 500,000 engines from the efficient EA 211 range, and 355,000 MQ 200 manual transmissions. In 2024, Škoda Auto celebrated 125 years of in-house engine development and production, having reached a total output of 15 million engines – a testament to its status as one of the world’s longest-established engine manufacturers.

Additionally, the expanded production line in Mladá Boleslav delivered 227,000 traction batteries for electric vehicles based on the MEB platform. These are installed in Škoda vehicles and other Volkswagen Group brands like Volkswagen, Audi, and SEAT/CUPRA. An additional 53,600 batteries were produced for plug-in hybrid models. In December 2024, Škoda Auto reached the milestone of 1 million battery systems produced since 2019.

The carbon-neutral Vrchlabí plant, celebrating 160 years of operation in 2024, achieved an output of 710,600 seven-speed DSG 200 automatic transmissions in 2024. These are used in Škoda vehicles as well as other Volkswagen Group models.

Performance and importance of Škoda’s production abroad

Škoda Auto leads operations in India on behalf of the Volkswagen Group and its brands. The country serves as Škoda’s second base outside Europe and a future export hub, capitalising on sales potential in regions such as ASEAN, the Middle East, Australia, and New Zealand.

In 2024, Škoda Auto produced 32,800 vehicles at its two Indian plants. The Pune facility manufactures the Slavia and Kushaq models, and in December 2024, production of the brand-new Kylaq compact SUV began, accompanied by an expansion of production capacity by 30%. The Kylaq will contribute to the brand’s annual sales target of 100,000 cars in India by 2026. The local logistics centre prepares Slavia and Kushaq models as completely knocked-down (CKD) kits, which will be assembled at a newly built plant in Vietnam. Meanwhile, production of the Kodiaq SUV continued last year at the facility in Chhatrapati Sambhajinagar (formerly Aurangabad).

Since December 2023, the Volkswagen Group’s plant in Bratislava, Slovakia, has been producing the new-generation Superb. In 2024, 54,500 units of this model rolled off the production line. Development of the Superb, alongside its sister model, the Volkswagen Passat, was entrusted to Škoda as part of the Beta+ project.

In China, Škoda vehicles were produced in the cities of Changsha, Ningbo, and Nanjing. The 2024 portfolio included the Octavia, Octavia Pro, Kamiq, Kamiq GT, Karoq, Kodiaq, and Superb, with total production reaching 15,200 vehicles.

In Solomonovo, Ukraine, assembly of the Karoq SUV continued.

Advancing internationalisation by expanding Škoda Auto’s global footprint

Throughout 2024, Vietnam – one of ASEAN’s most dynamic markets – saw intensive preparations for the production of the Slavia and Kushaq models from knocked-down kits imported from India. Series production of the Kushaq is scheduled to launch in the first quarter of this year. Vietnam will also serve as a gateway to other ASEAN countries.

In Kazakhstan, the car manufacturer assembles the Kodiaq, Karoq, Kamiq and Octavia from semi-knocked-down (SKD) kits. Over 1,400 vehicles were produced last year following Škoda’s re-entry into this market. In 2025, the company plans to expand local SKD assembly to include the new generation of Superb.

SOURCE: Škoda