Tech start-up Pentaform has devised a potential solution to e-waste: making gadgets that dissolve in water and leave behind only their electronic components for recycling.

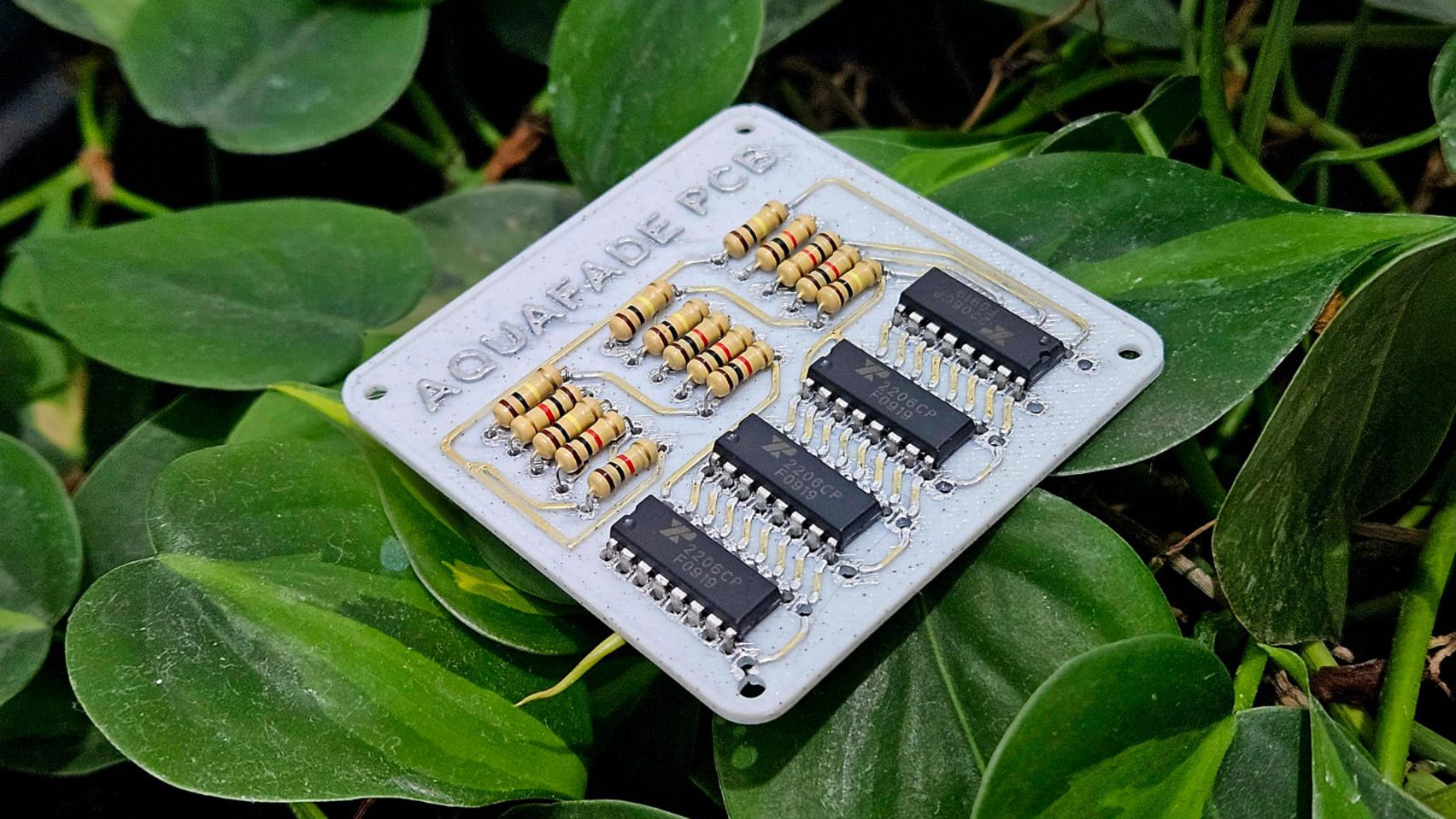

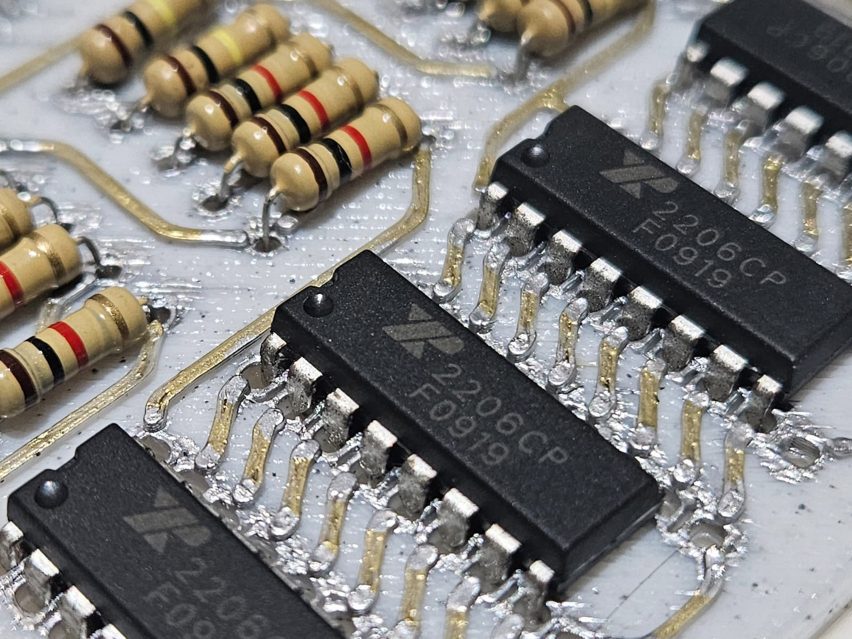

Pentaform’s idea involves making both the housing of an electronic product and its circuit board from a type of biodegradable and fully water-soluble plastic that the company is calling Aquafade.

The product – for instance, a computer or remote control – is given a thin waterproof coating on the outside to protect it from moisture, but when its housing is opened and the whole thing is submerged in water, it completely dissolves in six to eight hours.

As the plastic starts to break down, the valuable electronic parts can be easily separated from the material by hand, and the remainder of the plastic-water mixture is tipped down a sink or toilet so it can finish decomposing in the sewage system.

Pentaform co-founders Samuel Wangsaputra and Joon Sang Lee came up with Aquafade out of frustration with both e-waste and biodegradable plastics.

According to the duo, biodegradable plastics usually ends up in landfill rather than proper composting facilities and enters the environment as microplastics.

They are also critical of the carbon emissions generated from composting sites and waste transportation, which they think could be reduced.

With Aquafade, there is a shortcut to the best processing facility and no microplastics are left behind, they say.

“It’s the highest probability that people will actually biodegrade the product, because it dilutes in water, it gets transported through the sewage system, and it biodegrades with the bacteria in a sewage facility,” Wangsaputra told Dezeen.

Wangsaputra’s inspiration for Aquafade came from an everyday source: dishwasher detergent pods. Aquafade is made from the same type of synthetic polymer, called polyvinyl alcohol (PVOH), but used in bulk rather than as a thin film.

According to Pentaform, the material is durable, with similar mechanical properties to ABS – the polymer used as standard for computer parts – and can be injection moulded using the same machines. It is also commonly used for 3D printing.

Wangsaputra and Lee have been working with scientists Enrico Manfredi and Meryem Lamari to develop the polymer for their intended use, and also to develop the coating that will protect products from degrading upon exposure to moisture in the air and on surfaces.

“We want the coating to prevent the ingress of moisture but also we want the coating to make it a bit tougher, to make it stiffer and to allow it to take a bit more punishment,” said Manfredi. “We’ve actually found formulations to do both in isolation and now the next stage is combining the two compositions.”

The coating consists of two other common types of plastic: polyurethane and polydimethal siloxane, otherwise known as silicone.

These are typically non-toxic, and while they are not usually thought of as biodegradable, Pentaform’s scientists are confident that given the thinness of the coating and the bacteria in the sewage system, these too will break down completely.

“Polyurethane does break down – not quickly, but it does break down,” said Manfredi. “In waterways, we think it will break down much faster, because the activity of bacteria in sewage plants is actually pretty incredible.”

He says it is similar to how wastewater treatment plants already cleanse toxic compounds from soaps and detergents, with the local bacterial fauna adapting to whatever they are given to eat.

“You can kind of think of it as a watery composting facility,” he added.

Pentaform’s vision for Aquafade is to both license the material to other companies and to release their own products.

They have a headstart on the product, having previously designed and released a device called the Abacus computer that they now intend to update with Aquafade in place of recycled ABS plastic.

The product constitutes a computer housed inside a keyboard that can be connected to a TV screen for use. It targeted Wangsaputra’s home market in Indonesia, where most rural households do not have a home computer but do have a TV, and has found some popularity.

Pentaform has only been developing Aquafade since late 2023 and is now among the finalists for the Terra Carta Design Lab prize, which recognises student-led projects focusing on sustainability, and which Wangsaputra qualifies for as a recent design graduate of London’s Royal College of Art.

Wangsaputra’s vision is for the material to be more broadly adopted in consumer electronics. He says that if Aquafade can replace even one per cent of e-waste, it would prevent 140,000 tonnes of toxic and carcinogenic materials from potentially entering the environment.

“If we keep on bringing out these products that are quite radical, hopefully one of them will get accepted by the market and we could somewhat change the way the industry works,” said Wangsaputra.

The winners of the previous Terra Carta prize included the Tyre Collective’s tyre rubber-catching device and the Zelp muzzle for filtering methane out of cow burps.