Researchers often test experimental pharmaceutical therapies using lab-grown human tissues. Unfortunately, creating these materials can be complex and costly, leading many researchers to turn to alternative approaches such as 3D bioprinting—itself a slow, painstaking process. Now, however, a new printing system is showing promise for dramatically shortening the time needed to create lab-grade tissue samples. And instead of layering delicate cellular material, the tool relies on acoustic waves to assemble a wide array of biological components.

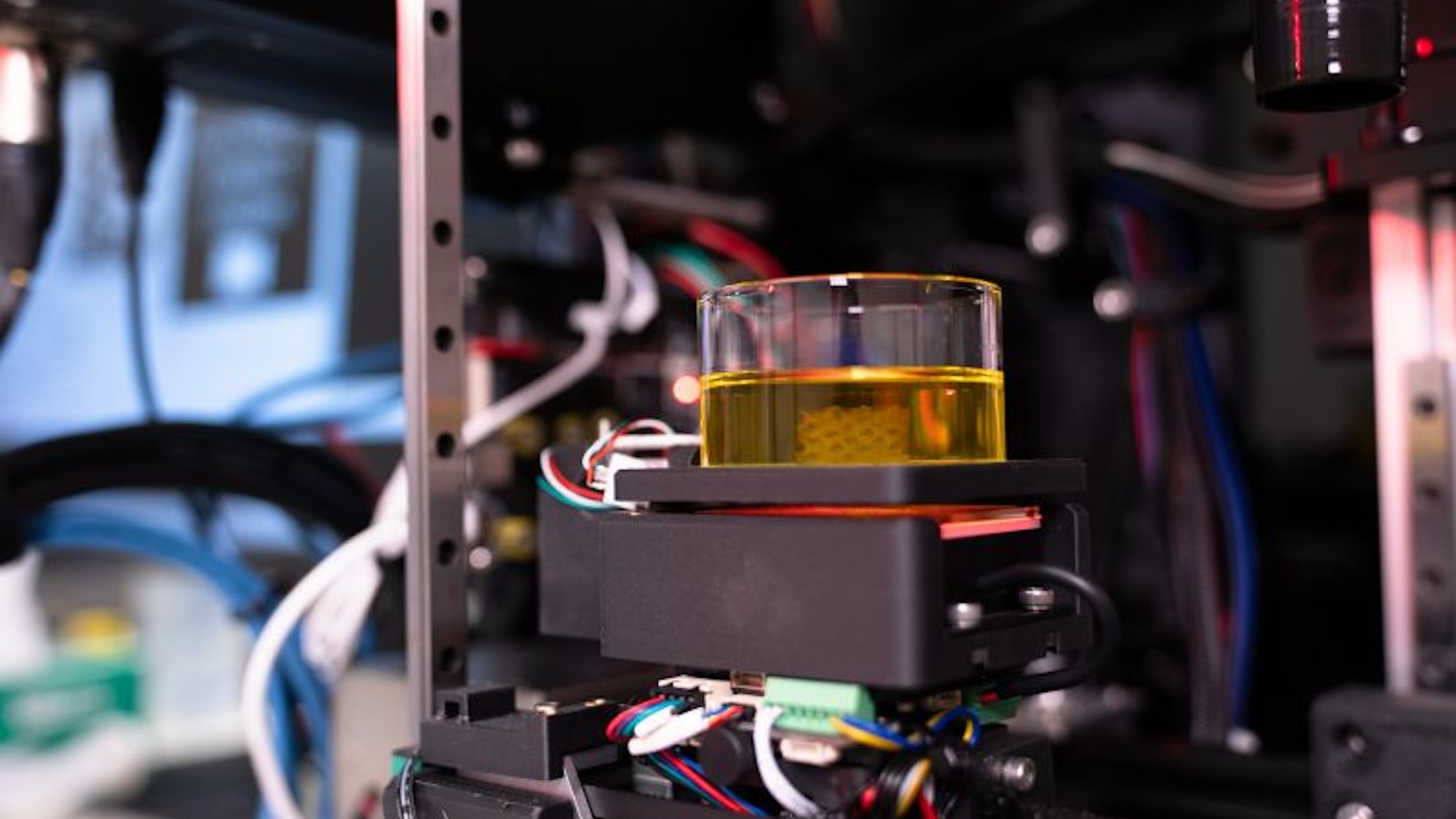

A biomedical engineering team at the University of Melbourne’s Collins BioMicrosystems Laboratory recently designed a new machine capable of what they call “dynamic interface printing.” As detailed in a study published in the journal Nature, the 3D bioprinter can already produce samples ranging from soft brain matter to denser bone and cartilage while overcoming many current industry hurdles.

“Just as a car requires its mechanical components to be arranged precisely for proper function, so too must the cells in our tissues be organized correctly,” David Collins, head of the Collins BioMicrosystems Laboratory, said in a university profile. “Current 3D bioprinters depend on cells aligning naturally without guidance, which presents significant limitations. These issues often include accidentally damaging the cells during printing, as well as limitations on tissue structure complexity.”

“Incorrect cell positioning is a big reason most 3D bioprinters fail to produce structures that accurately represent human tissue,” added Collins.

[Related: Scientists have 3D bioprinted functioning human brain tissue.]

Standard bioprinting currently also requires a two-step process. First, equipment slowly constructs a structure made of living cells layer-by-layer, often over the course of several hours. That amount of time frequently threatens the viability of cells due to their exposure in the lab. Once completed, researchers must then physically transfer tissues from the printer to lab plates for imaging and analysis. This final stage often results in damage to cell cultures that renders them useless.

His team’s 3D printer, however, offers an alternative that is both safer, more customizable, and much faster. Unlike most 3D printing strategies, the new device uses soundwaves to vibrate microscopic bubbles in desired directions to arrange specific cells. Once situated in place, researchers can manipulate these base structures to grow and mature into more complex human tissues.

The speed at which the bioprinter finishes these tasks is also exponentially quicker than layer-based 3D printers. At roughly 350 times the pace of traditional options, the new method only takes a few seconds to complete a job. Another benefit comes from its ability to print directly onto a lab plate, ensuring the tissue growths remain undisturbed, sterile, and less prone to damage.

The University of Melbourne researchers believe that with additional testing and improvement, medical facilities may one day possess 3D bioprinters able to use a patient’s harvested cells to produce hundreds of miniature models of their particular disease within only a few minutes.